Getting BIM Moving in A Large Firm

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

2006-10-12 07:20 PM

So, when Ben posted his first post here in hopes of gaining some information on which software would best suit the needs of our firm, we really gained more information about what BIM is and how it can affect our company. Thank you all for your responses to the posts by the way. Our firm has now made the commitment that every project we do will be on a BIM platform no matter how big or small and we are currently getting ready to complete projects whose sizes vary from 800,000 square feet to 10,000 square feet. The point in this post is to begin the conversation of the next phase of BIM. We have made our decision about software (ArchiCAD) and we are fully committed to the cause from the top down.

The Pace of the Process:

So, one of the first challenges that we are encountering in dealing with the number of users we have here is to get everyone up to the same level without hampering power users by restricting their efforts. We have users who are more than able to tackle some of the more intricate and complicated functions of ArchiCAD and really use it for a true BIM environment. However, most of our users are not ready for that step. Our goal is to move everyone into ArchiCAD, get them modeling and drafting and just using the software in an efficient manner. Then we can focus on the next steps. Unfortunately, that is a long process and at time we feel that we are holding people back from really excelling at the software and the process. How can we allow them to move at a pace to the point that we don’t lose the standardization of the process and create a large gap in our user base?

Who are the Right People?

The goal of our use of ArchiCAD and BIM is not to work faster but to work more efficiently. Basically because with efficiency inevitably comes speed. The increase in efficiency should allow us to do two things, work with few people on a project team and complete more work with the same amount of staff. In order to do this however you need “the right people.” Who are the right people and what makes them the right people? Now by right people we could care less about the skills on the computer, it is certainly a factor but now the deciding one. Everyone can be trained. We have found that there are people who are just more naturally adept at the BIM process. We have our theories on why, what would you guys say makes one person ready for this transition than the other?

The Future and the Next Step:

Lets make an assumption here and say that there are probably not many architecture firms in the world who do not use computer generated 3D modeling in one for or another, even if only SketchUp. That being the first phase and the next steps which we are beginning to take and will most likely be able to implement to the entire AEC industry within the next few years, what is the next step? Paperless job sites? Estimation of materials for recycling? Or perhaps we will begin to close the gap on our closely related cousins in the aeronautic and nautical design and manufacturing world and immerse ourselves in CAD/CAM manufacturing. Now, I am well aware that there are a few firms in the world who already make use of this type of technology, what I mean is that it becomes an industry standard practice. Where does everyone see the technology taking us in the next 3 years? 5 years? 10 years? I will not bore you all with elaboration on my interest in the CAD/CAM world, if you would like to discuss it with me please feel free to get in touch. However, I will ask does anyone else think that the design/build firms of the world will be on the forefront of the 4D revolution or will BIM possibly allow architects and engineers to take back some of the responsibilities we used to have as master builders?

So, thank you to everyone in advance for responding to these questions. I know they are probably not as thought provoking as Ben’s post of a few years ago, but I hope interesting none the less. Thanks again.

- Labels:

-

BIM Management

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

2006-10-12 09:27 PM

PivoArch wrote:In setting up K&A's 30 users, a couple things became evident over time:

So, one of the first challenges that we are encountering in dealing with the number of users we have here is to get everyone up to the same level without hampering power users by restricting their efforts. ...Our goal is to move everyone into ArchiCAD, get them modeling and drafting and just using the software in an efficient manner. ... How can we allow them to move at a pace to the point that we don’t lose the standardization of the process and create a large gap in our user base? .

1) Come up with a level of standardization that is teachable and definable. Make sure people know EXACTLY what is expected of them as a minimum. Yes, it's a pain to document and explain, but it gives people a guide. Pay them to learn it. That time will pay you back.

2) Train them on that standard, pushing them for performance ABOVE that level. The standard is a minimum acceptable level for keeping their job.

3) Let your power users spread their wings. Make them the "CAD Team Leader" and let them push HARD. Other people on their teams will learn from them. When they are doing projects dramatically faster than others are, it's obvious that they are more effective and should be rewarded for it. Encourage them to teach their methods to others. Some people might be less intimidated by a fellow staff member than a CAD Manager, BIM Coordinator, or other person in a position of authority.

Others might argue, but this worked well for me with their users, very few of whom were power users. Looking at them now (3 years later), they are a pretty strong group of CAD users.

Who are the Right People?I disagree everyone can be trained. Some are simply unwilling. Others truly lack the foundation skillset (basic mousing and computer skills to click icons and type commands). Others lack the architectural/construction knowledge. Some are complacent with their current skills.

The goal of our use of ArchiCAD and BIM is not to work faster but to work more efficiently. ... In order to do this however you need “the right people.” Who are the right people and what makes them the right people? Now by right people we could care less about the skills on the computer, it is certainly a factor but now the deciding one. Everyone can be trained. We have found that there are people who are just more naturally adept at the BIM process. We have our theories on why, what would you guys say makes one person ready for this transition than the other?

Yes, some are more adept at computer software. Some can truly see how a condition will be built and how it should be modeled in a BIM environment. They see what tools can get them a good-looking construction model/document that can also be scheduled and reported at the same time it can be edited quickly and effectively.

To me, the more "3D aware" people, those who truly can understand shape and construction methods at the same time, work the best. Those architects that are best used as paper pushers or colorers will never be as strong with BIM.

Most importantly, though, they must CARE about their work. They must be proud when their projects go smoothly and be ashamed when they do not. They must see their own power to influence the profitability and efficiency of their projects and be held accountable when their performance is not up to standard.

I find that generally, a true "architect", who is part designer, part engineer, part artist, part accountant, part contractor... the true master builder, may have problems with learning the technical end of computer software but has no problems seeing what needs to be done in a BIM software and even directing a team in that direction. It's a rare instance of someone who technically does not have the skill but has the correct overall vision of what needs to be done. They may not be able to use the software well themselves, but make solid team managers since they know what to demand from their teams.

The Future and the Next Step:Answer me this: how does a carpenter use a paperless drawing? Does he carry a laptop with him? A PDA? A plasma TV? At the end of the day, paper remains the easiest and (by far) cheapest way for the guy in the field swinging the hammer. Sure, you can deliver electronic drawings, but someone somewhere will probably be printing them.... assuming that there is still someone in the field swinging a hammer. If it's all pre-fab and assembled onsite, then it's another story. Then CAD/CAM becomes a little more applicable.

what is the next step? Paperless job sites? Estimation of materials for recycling? Or perhaps we will begin to close the gap on our closely related cousins in the aeronautic and nautical design and manufacturing world and immerse ourselves in CAD/CAM manufacturing. Now, I am well aware that there are a few firms in the world who already make use of this type of technology, what I mean is that it becomes an industry standard practice. Where does everyone see the technology taking us in the next 3 years? 5 years? 10 years? I will not bore you all with elaboration on my interest in the CAD/CAM world, if you would like to discuss it with me please feel free to get in touch. However, I will ask does anyone else think that the design/build firms of the world will be on the forefront of the 4D revolution or will BIM possibly allow architects and engineers to take back some of the responsibilities we used to have as master builders? .

I think it depends on the industry. In housing/residential, there is a lot more contractor control. In commercial, it can depend on the client and their willingness to demand levels of service from a team, knowing it will cost them more.

I think in a lot of ways, construction management firms and larger contractors have taken a large amount of control away from architects and it will be a hard fight to get that back.

I think part of that depends on Graphisoft and AutoDesk and how well they can push the construction end of the industry. As long as they are walking around the site with printed drawings, there is only so much architects can do to push a paperless environment. That's why most of my efforts go to making the best printed documents possible.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

2006-10-13 03:31 PM

That is all very useful insight, it falls in line with our recent goal to create a minimum model standard. I was wonder what types of things you would suggest we standardize on and when should we leave it to the users best judgement to figure it out on thier own. I am always worried that too much hand holding or too many rules and the users are not going to explore and possibly improve on our methods, but ina firm where we may have 20 people on any given project accross multiple offices it becomes important that somone can jump in and understand the methods and reasons behind the creation of a model in a certain way. Any information you might have to help with that direction would be incredibly useful in our efforts.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

2006-10-13 03:40 PM

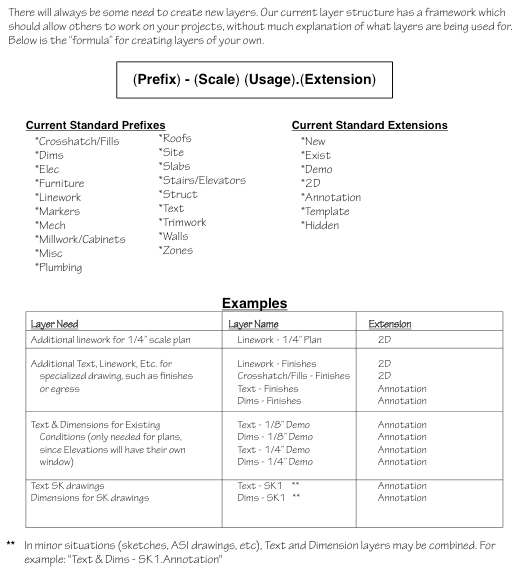

1) Graphic Standard Manual. "Drawings shall look like this." No questions, no deviation, it must look like this when printed. Rarely updated.

2) Production Standard manual: Archicad project structure which defined pen and layer usage, project structure (file content, what is modeled and what is drawn, module organization, project folder structure etc). All tied back to the graphic standard. Updated with each release of Archicad to accomodate new functions like Plotmaker/Archicad integration.

3) A "Best Practices" manual. Every task (like making a DWG or creating a new project file) is broken down into a single-page tip sheet. If someone cannot perform a task, they can look it up. I always maintained ONE page. If something spanned longer, I broke it into smaller tasks. It grew over the years until it really became the office knowledge base. Once in a while a better method comes along and it gets updated. Everything in it tied back to the Graphics manual and the Production Standard. Updated as needed.

The attached screenshot is a page from the Production Standards manual describing the layer standard. Wherever possible, I tried to make recipes for creating things of their own, not make lists.

K&A has weekly CAD training (lunch & learn) seminars. The majority of the CAD team is always there and I've always pushed them for ideas and suggestions. I imagine that's easier with 20 people than with 200 though.

I've rather successfully impressed upon them that the standards are open to change if someone has a good idea, but they are law until that idea is approved as a different way to do something. I'm sure we've all seen someone go off on their own with some great idea that blew up in their face.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

2006-10-13 03:53 PM

All of these are maintained as PDFs and have revision dates on them. I always push them to use the electronic ones, not any prints that might be laying around, since they could be outdated.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

2006-10-13 07:45 PM

We have been trying to work with the NCS for our base and modifing it for our needs as we see fit. As for working in ArchiCAD I can give you an example of one of our on going debates. Sections and Details:

I am of the theory that all elevations and building sections should be live and generated form the model. However, I do feel that things like wall sections, details, and the such should be set to DRAWING and then copied to the side (for now), this maintains the link fo rhte tag and allows you a comparison to the information coming form the model. I think this also fits in well with the way our firm works in throwing bodies at a project when a deadline nears. The none live detail means that anyone can be brought in to work on that detail without an intimate knowledge of the model and without accidentally messing the model itself up. Our power users however, wanting to keep to the true BIMness of the program want everything to be live.

We have not come up witha good way to make everyone happy on this issue other than to have to ways to do the same task, now i'm not saying that we will never do live details but I think fo rthe start up effort the none live details are the way to go.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

2006-10-13 09:24 PM

PivoArch wrote:I convinced K&A's management a long time ago it was worth the money to buy lunch for the training seminars. It's usually just pizza & soda, but it draws people in.

It is also hard because I run my meetings as a bring your own lunch and I have to compete with the other free lunch meetings.

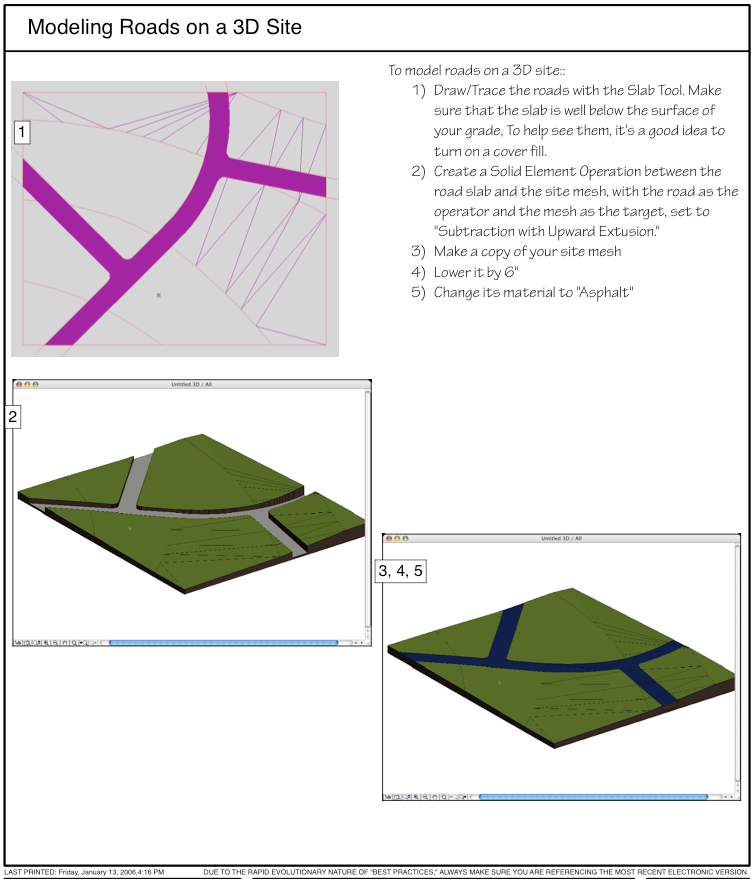

I am of the theory that all elevations and building sections should be live and generated form the model. However, I do feel that things like wall sections, details, and the such should be set to DRAWING and then copied to the side (for now), this maintains the link fo rhte tag and allows you a comparison to the information coming form the model. I think this also fits in well with the way our firm works in throwing bodies at a project when a deadline nears. The none live detail means that anyone can be brought in to work on that detail without an intimate knowledge of the model and without accidentally messing the model itself up. Our power users however, wanting to keep to the true BIMness of the program want everything to be live.The guideline I give is 1/4" = 1'-0" scale. Anything 1/4" scale or smaller (1/8", 1/16") AND visible in more than one drawing (plan, section, schedule, etc) must be modeled. Anything larger scale (3/4", 1 1/2", etc) should be based on the model, but is expected to be a hybrid of drawn 2D and 2D based on the model.

It would be nice to model more, but the tools are not there to really model roof membranes and weep holes.

We have not come up witha good way to make everyone happy on this issue other than to have to ways to do the same task, now i'm not saying that we will never do live details but I think for the start up effort the none live details are the way to go.Honestly, I've seen a lot of projects where the details are completely 2D because they are copied from other jobs or from a standardized detail kit (like door and threshold details, window headers, etc). At that point, you kind of know there is no modeled content in them.

As much as I hate to say it, almost any larger company is probably going to need its own custom object library too.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

2006-10-13 09:44 PM

As much as I hate to say it, almost any larger company is probably going to need its own custom object library too.Well I can say we do have that. We have built our own library and we don't even need to load the ArchiCAD Library anymore.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

2006-10-13 09:46 PM

PivoArch wrote:WOW. I'll bet that was fun....As much as I hate to say it, almost any larger company is probably going to need its own custom object library too.Well I can say we do have that. We have built our own library and we don't even need to load the ArchiCAD Library anymore.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

2006-10-14 03:47 AM

TomWaltz wrote:Great work Tom. It looks like you've taken my recommendations farther than anyone else I've worked with. Of course I haven't seen James Murray's docs lately

I took an approach of:

1) Graphic Standard Manual. "Drawings shall look like this." No questions, no deviation, it must look like this when printed. Rarely updated.

2) Production Standard manual: Archicad project structure which defined pen and layer usage, project structure (file content, what is modeled and what is drawn, module organization, project folder structure etc). All tied back to the graphic standard. Updated with each release of Archicad to accomodate new functions like Plotmaker/Archicad integration.

3) A "Best Practices" manual. Every task (like making a DWG or creating a new project file) is broken down into a single-page tip sheet. If someone cannot perform a task, they can look it up. I always maintained ONE page. If something spanned longer, I broke it into smaller tasks. It grew over the years until it really became the office knowledge base. Once in a while a better method comes along and it gets updated. Everything in it tied back to the Graphics manual and the Production Standard. Updated as needed.

The attached screenshot is a page from the Production Standards manual describing the layer standard. Wherever possible, I tried to make recipes for creating things of their own, not make lists.

K&A has weekly CAD training (lunch & learn) seminars. The majority of the CAD team is always there and I've always pushed them for ideas and suggestions. I imagine that's easier with 20 people than with 200 though.

I've rather successfully impressed upon them that the standards are open to change if someone has a good idea, but they are law until that idea is approved as a different way to do something. I'm sure we've all seen someone go off on their own with some great idea that blew up in their face.