Turn on suggestions

Auto-suggest helps you quickly narrow down your search results by suggesting possible matches as you type.

Showing results for

Turn on suggestions

Auto-suggest helps you quickly narrow down your search results by suggesting possible matches as you type.

Showing results for

- Graphisoft Community (INT)

- :

- Forum

- :

- Libraries & objects

- :

- How to make this chair?

Options

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Pin this post for me

- Bookmark

- Subscribe to Topic

- Mute

- Printer Friendly Page

Libraries & objects

About Archicad and BIMcloud libraries, their management and migration, objects and other library parts, etc.

How to make this chair?

Anonymous

Not applicable

Options

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

2008-11-12 07:10 AM

2008-11-12

07:10 AM

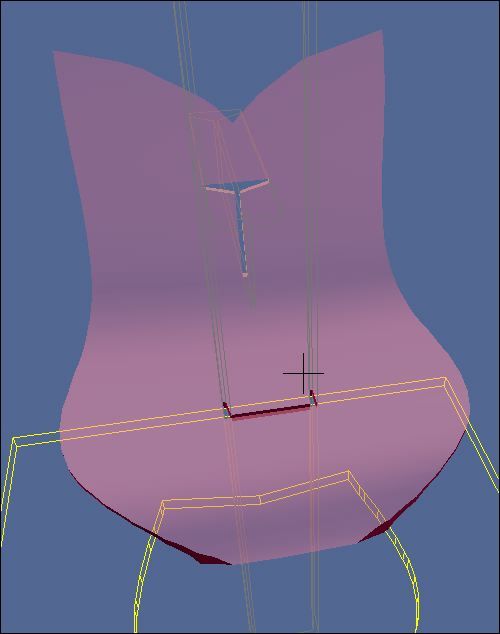

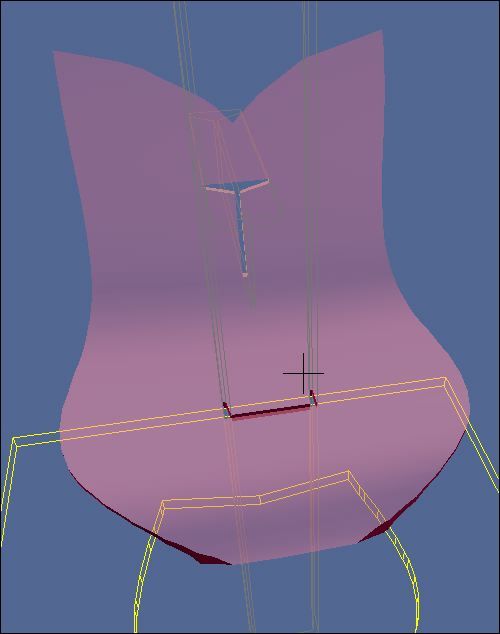

Does anyone have any pointers on how to make this (obviously another program may be easier to model in but I don't have access to another program).

Any tips, tutorials, help etc would be greatly appreciated.

7 REPLIES 7

Options

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

2008-11-12 08:37 AM

2008-11-12

08:37 AM

It is four steps, but these steps use the complex profile to form the seat and the Solid Element Operation to cut the holes.

How much experience do you have in Archicad?

What version of Archicad?

Do you have the exact dimensions for this chair or only a photo?

How much experience do you have in Archicad?

What version of Archicad?

Do you have the exact dimensions for this chair or only a photo?

Dwight Atkinson

Anonymous

Not applicable

Options

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

2008-11-12 09:10 AM

2008-11-12

09:10 AM

I've used ArchiCAD on and off for 3 years, however I haven't used 'complex profile' or 'solid element operation' before. So I would say more of a beginner than anything.

I'm currently using ArchiCAD 11.

The dimensions I have are 470mmW x 530mmL x 860mmH /450mm H seat. (I did have a side and front elevation but I can't seem to find it right now).

I'm currently using ArchiCAD 11.

The dimensions I have are 470mmW x 530mmL x 860mmH /450mm H seat. (I did have a side and front elevation but I can't seem to find it right now).

Options

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

2008-11-12 09:29 AM

2008-11-12

09:29 AM

You've just identified the fundamental problem everyone has in trying to make a nice object: not enough information about the object to be modeled. With what you know know, it will be really crude. Do you have one of these chairs? It usually takes way more time to gather the data than it does to execute the model.

My solution is just approximate, but is close enough. Here are the steps once you have accurate data and dimensioned views:

The seat and back: make a complex profile of the unified seat and back section. Apply it using a wall that curves along the front of the seat lip. You get a solid plastic shape. See the Wiki for more on Complex Profile.

Make a Complex Profile to match the holes in the seat. Use it as a slightly tilted column to subtract the holes from the seat using a Solid Element Operation. See the Wiki for more on SEO.

Make a Complex Profile to match the holes in the back. Use it slightly tilted beam to subtract the holes from the back and to sculpt the top of the back using a Solid Element Operation.

Tapered legs: Here is where it gets squirrely, because Archicad doesn't want a tapered thing narrower at the bottom. Here you use a roof with a thickness the height of each leg. Use the roof edge angle control to precisely taper the legs. Or, you can use roofs to SEO slabs or something if the legs also tilt..... but we need to know the dimensions of the elements in order to be accurate.

Good luck. You will certainly learn a lot about Archicad.

My solution is just approximate, but is close enough. Here are the steps once you have accurate data and dimensioned views:

The seat and back: make a complex profile of the unified seat and back section. Apply it using a wall that curves along the front of the seat lip. You get a solid plastic shape. See the Wiki for more on Complex Profile.

Make a Complex Profile to match the holes in the seat. Use it as a slightly tilted column to subtract the holes from the seat using a Solid Element Operation. See the Wiki for more on SEO.

Make a Complex Profile to match the holes in the back. Use it slightly tilted beam to subtract the holes from the back and to sculpt the top of the back using a Solid Element Operation.

Tapered legs: Here is where it gets squirrely, because Archicad doesn't want a tapered thing narrower at the bottom. Here you use a roof with a thickness the height of each leg. Use the roof edge angle control to precisely taper the legs. Or, you can use roofs to SEO slabs or something if the legs also tilt..... but we need to know the dimensions of the elements in order to be accurate.

Good luck. You will certainly learn a lot about Archicad.

Dwight Atkinson

Options

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

2008-11-13 05:37 AM

Anonymous

Not applicable

Options

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

2008-11-13 07:48 AM

2008-11-13

07:48 AM

Thanks for taking the time to help out Dwight.

Unfortunately I have to reinstall ArchiCAD so I can't try this out right now. But I will as soon as I can.

Am I going to be able to use a jpg in the background and use the complex profile tool and SEO?

Unfortunately I have to reinstall ArchiCAD so I can't try this out right now. But I will as soon as I can.

Am I going to be able to use a jpg in the background and use the complex profile tool and SEO?

Options

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

2008-11-13 07:55 AM

2008-11-13

07:55 AM

I can't see why not, unless you are mentally defective, or something, like permanently stuck in Flatland.

These things are so simple a fellow could even do them while drunk.

These things are so simple a fellow could even do them while drunk.

Dwight Atkinson

Anonymous

Not applicable

Options

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

2008-11-13 08:23 AM

2008-11-13

08:23 AM

Hehe. I know placing a jpg is easy I just wasn't sure it would work in conjunction with these instructions!