- Graphisoft Community (INT)

- :

- Forum

- :

- Modeling

- :

- Re: SIP WALL PANEL

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Pin this post for me

- Bookmark

- Subscribe to Topic

- Mute

- Printer Friendly Page

SIP WALL PANEL

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

2008-02-27

08:20 PM

- last edited on

2024-06-03

12:44 PM

by

Aruzhan Ilaikova

cheers guys

- Labels:

-

Composites

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

2008-02-27 08:44 PM

Also, what AC version and OS?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

2008-02-27 09:40 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

2008-02-27 10:03 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

2008-02-27 10:21 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

2008-02-27 10:28 PM

Basically two skins of OSB (oriented strand board) with 125-200mm of expanded polyurethane foam in between, often edged with a timber plate to allow fixing.

We are just starting to use these for a tiny extension locally, as a test for possible larger projects.

I have been thinking about how best to model them for a while but haven't really 'got around' to doing anything yet! The problem is they come in set lengths and widths and it is obviously more economical if you don't have to cut them down to size.

In order to begin to model a building with them, you would need to set up some kind of grid for each elevation which would give you the spacing of the windows. This could be achieved by making a panel library part with the preset sizes built in, and also the different options for the each of the edges. It would have to be storey sensitive also to be any use on plan.

This would give you the option of producing a fabrication list for all the panels, giving their size and quantities etc.

I still haven't sorted out fully in my mind how far to take the detailing. It could be a very sophisticated and powerful library part if you want to go in that direction.

It may well be that the SIPs manufacturer will do all the panel size calculating and you don't have to worry about detailing it. In which case a simple composite showing two skins and an insulation infill would be suitable. How detailed are your drawings going to be? Are you going to be responsible for the layout of the panels?

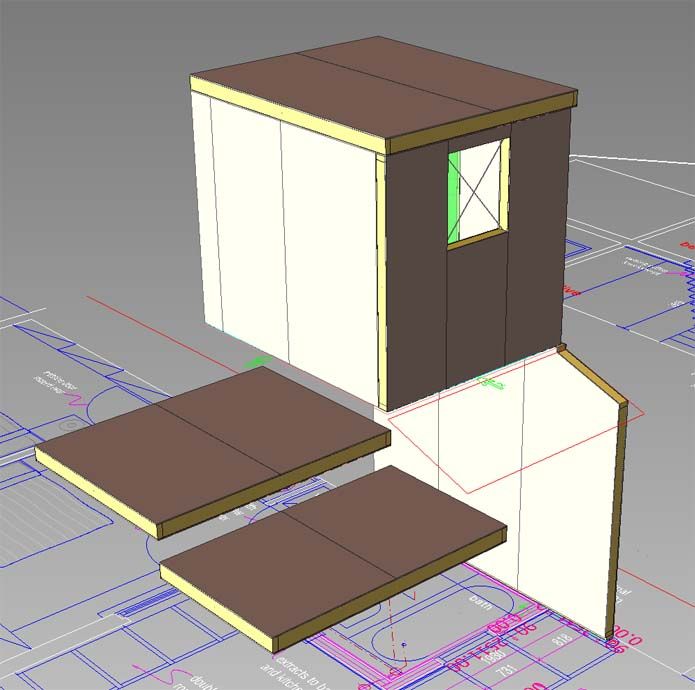

The SIPs manufacturer supplied us with a dwf 3d model of the extension, modelled over the top of the 2d drawings we supplied, using some kind of Autodesk product. They had actually modelled the individual panels. (Screenshot attached). You can see the importance of correctly showing how the panels meet and their respective priorities, otherwise they wont fit!

I would also be interested in seeing what others have done when dealing with similar prefabricated panels.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

2008-02-27 10:51 PM

I looked at the Cadimage Wall Framing tool long ago but got slammed and had issues with it where the base of a wall stepped. Could have been me, I'll check into it again as it shows promise. You may want to do the same.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

2008-02-27 11:15 PM